We incorporate our vehicles and weapon systems into new or existing networks and equip our customers with outstanding capabilities for military conflicts, asymmetric threats, and civilian security above and below water.

We provide effective defence against hazards along coastlines and in harbours. And we have a sure command of the integration of existing systems into complex networks, together with the associated communication techniques including encryption technologies.

Our depth of in-house production is unique. We develop and manufacture all the important components of our hardware and software in our own facilities. Our know-how ranges from metalworking and polymer processing, through our own PC board design and production, and up to the development and qualification of software for our equipments and systems.

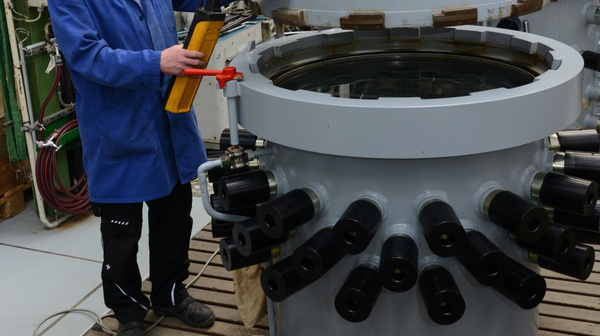

A company-owned test lake, large measurement tanks as well as testing stands for mechanical, electromagnetic and climatic load tests are all part of our comprehensive facilities.

The artificial intelligence of our autonomous vehicles is faulttolerant – we aim for the highest degree of operating accuracy. Time and time again, we probe the limits of what is physically possible, expand our knowledge, and then pass this competitive edge on to our customers in the form of superior products.

German Engineering means a passion for precision and innovation.

By doing so, we create the best possible foundation for perfect operator training and efficient servicing and maintenance. This we put into practice every day, because we are here to help our customers – everywhere in the world, right around the clock.

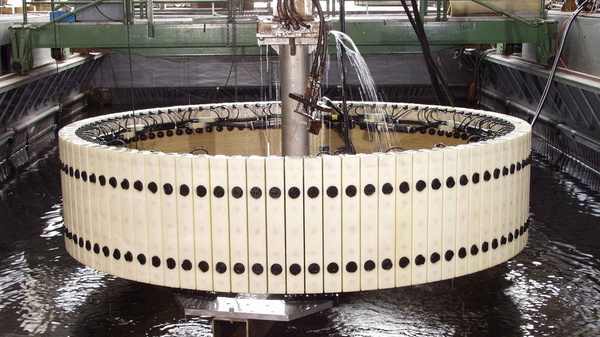

ATLAS ELEKTRONIK enjoys an excellent reputation of many years' standing amongst navies all over the globe. The source and essence of this renown is to be found in the ATLAS sonar systems. Their quality and performance capabilities depend to a great extent on the workmanship of the “wet ends”. The development of these sensors, with due consideration for their constant exposure to sea water, and of the associated software for signal processing and evaluation belongs to the tasks of the newly established ATLAS Sonar Center.

The product philosophy of the team is clearly defined: Even the best evaluation algorithms will only achieve the best possible results if the input signals are clean. For this reason, the wet ends are truly the starting point for all high-performance sonar systems. The interplay of hardware and software then produces the end result that constitutes the excellent name of ATLAS sonars.

Overlaps in the development of sonar functional chains with the other corporate function, Engineering, are intentional. The topics of user interfaces (HMI – human-machine interface), inboard hardware and simulation for testing purposes and for training the customer are all addressed in Engineering. But together the two areas show what is possible from a developmental viewpoint. In many respects, there is the sense of a new beginning.

The agenda with new products, technologies and methods is long and exceeded only by the imagination of the staff members. The innovative ideas include, for example, a passive medium frequency sensor for submarines, for which fiber optics are used outboard with the wet ends for the first time. Mechanical components and electronics developed anew for this concept permit vertical beamforming, i.e. the detection of signals not only across the horizon but also along the water column. Novel manufacturing processes allow the introduction of a new pricing model. Faster, better, leaner: the objective of the new Sonar Center is fast becoming reality.

New technologies are also being applied to the underwater microphones. Hydrophones that use optical methods to convert the sound pressure into electrical signals, and therefore replace the conventional technology with piezoelectric crystals or ceramics, may represent another milestone in sonar development.

In the fields of design and production, 3D printers have for some time been allowing unconventional methods in handling plastics-based materials. New sintering processes are now transferring the advantages of 3D printing to metallic materials.

Innovative designs that until now only existed in the conceptual form because they could not be implemented yet, even with the most modern CNC or casting techniques, are now becoming viable with metal 3D printing, allowing the construction and manufacture of completely new components, and hence new sensors.

For the Sonar Center too, it is vital to utilise the advantages offered by a centralised organisation in daily work, while avoiding its drawbacks. To do this, small, temporary teams repeatedly come together to combine the elements needed at that point for a particular task from the existing competence catalogue and to yield the required results. At the same time, “bridges of communication” are always built to the external client, for example through the participation in reviews and meetings. This temporary departure from the classic matrix, the work with small ad hoc teams and the application of other agile methods is paying off in every respect. This is true for the product quality, the product costs, and the motivation of the staff. Becoming Europe’s competence center for sonar is the declared goal of the Sonar Center set up in 2016. And our colleagues are getting closer to this goal day by day.

ATLAS’s Production area, with several hundred employees at the Bremen-Sebaldsbrück location alone, operates with technologies that have been mastered by only a few companies worldwide. The list of competencies is long: it includes sonars with ceramics, complex, highly specialised electronics, wiring systems, obsolescence management and offset consulting. In essence, the goal is always to meld physics, information technology and a wealth of experience to obtain a result that will serve customers in the best possible way.

Extremely robust yet supremely sensitive

ATLAS sonars are able to discern sounds that, in terms of their loudness, lie far below the threshold of human hearing. The technical challenge lies in amplifying the acoustic vibrations in the water, which are converted by the reception components of the sonar into tiny voltage pulses, with an extremely low noise level and hence without distortion, and then making them available to the signal processing modules. This demanding task has to be performed in an aggressive environment, because the “wet ends” are constantly exposed to seawater. The plastics production department for transducer manufacture with comprehensive casting and cleaning equipment is continually expanded and modernised, and composite-fibre materials are used, to ensure that all tasks can be fulfilled as required.

Uniqueness and large-scale manufacture

Electronic parts, some with more than 1,000 connections, printed circuit boards with over 6,000 components, two main production lines handling 60,000 components per hour, usually in three-shift operation – these are just a few figures characterising Production at ATLAS.

Through the ATLAS EMS, the ATLAS Production area also makes its special capabilities available to external customers, thereby serving a client spectrum ranging from civilian and military aviation to medical engineering and industrial solutions.

However, the main client for Production remains our own enterprise. The primary focus is on the development and manufacture of the sonar portfolio, from the small surveying sonar through the sonar head of the world’s most modern heavyweight torpedo and up to complete sonar suites for submarines and surface vessels.

Today’s challenges include concurrent design processes and ever shorter cycle times from order intake to delivery of the first unit. Full traceability of all components within the scope of documentation requirements and product liability are also factors to be considered.

Obsolescence management plays an important role, particularly in the electronics industry. Usually, ATLAS is able to offer its customers feasible solutions long before a part, system component or complex unit is no longer functional.

Even the topic of offset and, with it, the aim of customers to locate engineering and production in their own countries with existing or newly developed capacities is familiar territory for ATLAS.